Understanding the Plastic Injection Molding Process for High-Quality Manufacturing

Understanding the Plastic Injection Molding Process for High-Quality Manufacturing

Blog Article

A Comprehensive Overview to the Plastic Injection Molding Innovation

Plastic shot molding stands as a foundation of modern-day production, providing unrivaled performance and accuracy in the manufacturing of complex plastic components. As the landscape of manufacturing progresses, recognizing the future trajectory of injection molding becomes increasingly essential.

Overview of Plastic Shot Molding

Plastic shot molding is a commonly made use of manufacturing process that enables the effective manufacturing of complex plastic parts with high precision. This innovation has ended up being a keystone in different sectors, including automotive, durable goods, and electronics, owing to its capacity to create large amounts of components swiftly and cost-effectively.

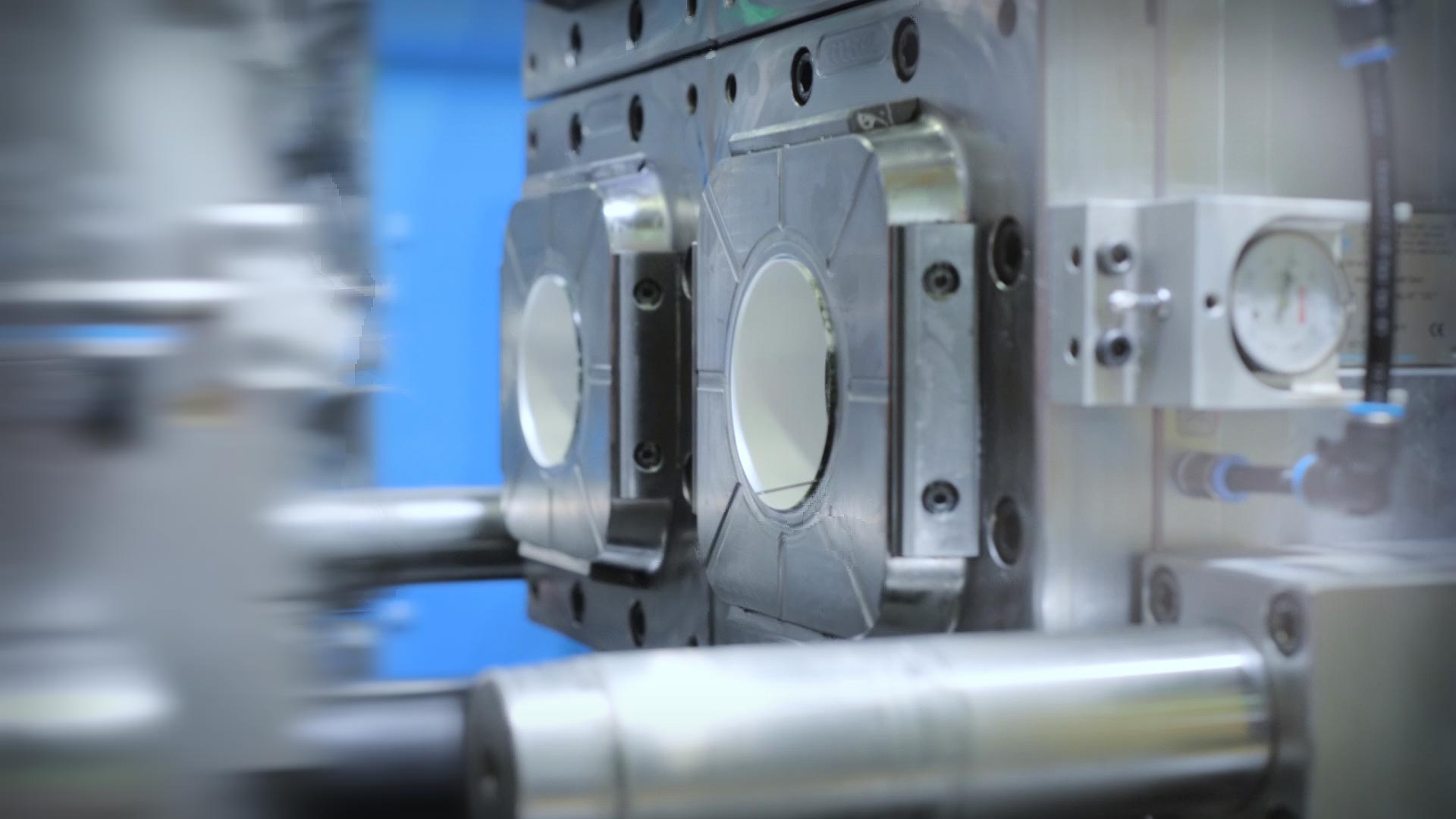

The procedure involves melting plastic granules and infusing the molten material into a pre-designed mold. As soon as cooled down, the mold is removed to expose the finished component, characterized by its intricate information and uniformity. The convenience of materials used in plastic injection molding, ranging from thermoplastics to thermosetting polymers, allows manufacturers to customize products to meet certain demands, such as flexibility, toughness, and resistance to warmth or chemicals.

Furthermore, the performance of this approach minimizes waste and reduces production costs, making it an eye-catching choice for organizations aiming to enhance their manufacturing procedures. As modern technology breakthroughs, technologies such as multi-material injection molding and the assimilation of automation proceed to improve the capabilities of plastic injection molding, making it possible for the creation of increasingly innovative items that satisfy the demands of modern markets.

The Shot Molding Process

Injection molding is an advanced production method that entails a number of essential steps to change raw plastic materials into completed items. The procedure starts with the prep work of plastic pellets, which are fed into a heated barrel. Right here, the pellets are thawed and co-opted to attain a consistent thickness.

As soon as sufficiently warmed, the liquified plastic is injected right into a precisely engineered mold and mildew under high stress. This action is crucial, as it allows the material to fill every dental caries of the mold and mildew, guaranteeing the final product accurately reflects the designated layout. The injection time should be carefully controlled to avoid flaws and guarantee efficient product use.

After the mold and mildew is filled up, it undertakes a cooling phase, where the plastic solidifies right into its last shape. This cooling process can vary in duration relying on the thickness and intricacy of the component. When cooled, the mold opens, and the finished product is ejected.

Trick Advantages of This Innovation

Among one of the most substantial advantages of shot molding modern technology depends on its capability to produce high quantities of accurate and regular components with marginal waste. This efficiency comes from the automated nature of the process, which considerably reduces manual work and the potential for human mistake. Consequently, suppliers can attain a high level of repeatability in their result, guaranteeing that each component satisfies rigorous high quality criteria.

One more trick benefit is the adaptability of materials that can be utilized in shot molding. A variety of thermoplastics and thermosetting polymers can be molded, permitting customized buildings to match specific applications. Additionally, the innovation sustains elaborate layouts and complicated geometries, which can be challenging to attain with various other manufacturing techniques.

Cost-effectiveness is likewise an essential benefit, especially for large manufacturing runs. The first financial investment in mold and mildews might be high, yet the long-term financial savings in product waste and labor make injection molding an economically sensible choice. Injection molding allows for rapid manufacturing cycles, making it possible for firms to react promptly to market needs and reduce lead times. These benefits solidify this article shot molding's position as a recommended production procedure across different sectors.

Applications Across Industries

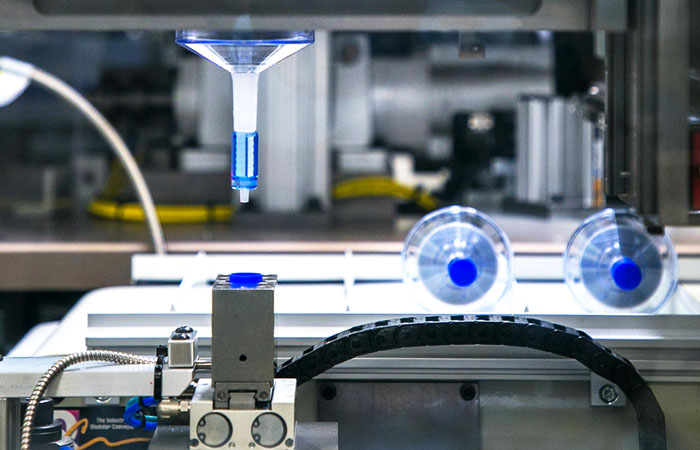

In the medical field, shot molding is vital for making high-quality, sterilized components, consisting of syringes, medical instruments, and housings for medical tools. The capability to keep limited tolerances and produce complicated geometries makes it a perfect selection for these applications. Furthermore, the product packaging market benefits from injection molding by creating a vast array of containers, closures, and dispensers that are both effective and cost-efficient.

The plaything sector counts greatly on injection molding to create colorful, resilient, and risk-free items that attract youngsters. The construction sector makes use of shot molding for producing various components, fittings, and elements that contribute to both functionality and design. Overall, the broad array of applications shows the essential duty of injection molding technology beforehand different fields.

Future Trends in Shot Molding

Accepting improvements in modern technology, the future of shot molding is poised for considerable change driven by developments in products, automation, and lasting techniques. One of one of the most noteworthy patterns is the advancement of recycled and bio-based polymers, which not just minimize dependence on nonrenewable fuel sources but additionally reduce ecological influence. As producers significantly prioritize environment-friendly services, these materials are becoming extra widespread in manufacturing.

Automation is another essential trend forming the industry. The assimilation of robotics and man-made knowledge right into the injection molding process enhances efficiency, precision, and manufacturing rate. Smart factories equipped with IoT tools enable real-time monitoring and predictive upkeep, lowering downtime and maximizing functional processes.

Furthermore, the shift in the direction of customized and small-batch production is obtaining momentum. Advanced technologies such as 3D printing and additive production enable rapid prototyping and the creation of intricate geometries that were previously unattainable. This change allows companies to respond extra efficiently to market needs and consumer choices.

Conclusion

In verdict, plastic shot molding innovation stands for official statement a cornerstone of modern-day production, using performance and convenience in creating intricate components across varied industries. The detailed evaluation of the injection molding process highlights its critical phases and advantages, while the exploration of applications emphasizes its prevalent relevance.

Plastic shot molding stands as a cornerstone of contemporary manufacturing, offering exceptional effectiveness and precision in the manufacturing of complicated plastic components (Plastic Injection Molding). The convenience visit this site of products made use of in plastic injection molding, varying from thermoplastics to thermosetting polymers, allows makers to customize items to fulfill details demands, such as resistance, flexibility, and strength to warmth or chemicals

Injection molding is an advanced manufacturing method that involves several important actions to transform raw plastic products into completed items.The versatility and performance of injection molding innovation have led to its prevalent fostering throughout numerous industries.In final thought, plastic shot molding modern technology stands for a cornerstone of modern-day production, offering effectiveness and adaptability in creating intricate components across diverse markets.

Report this page